Concrete Pipe Making Machines Manufactured in India with European Technology

PAKONA is not just into Packaging alone. Pakona has established itself into other areas like manufacturing machines for the Construction Industry. Pakona offers State-of-the-Art Equipments like Concrete Pipe Making Machines for Reinforced or Non-Reinforced pipes, Round pipes, pre-bed, Manhole chamber machine covers, Vertical cast RCC pipe machine, Box Culvert making machine, Risers, HDPE Liner Pipes, Vertical cast pipe, RCC cement pipe, Manhole chamber machine.

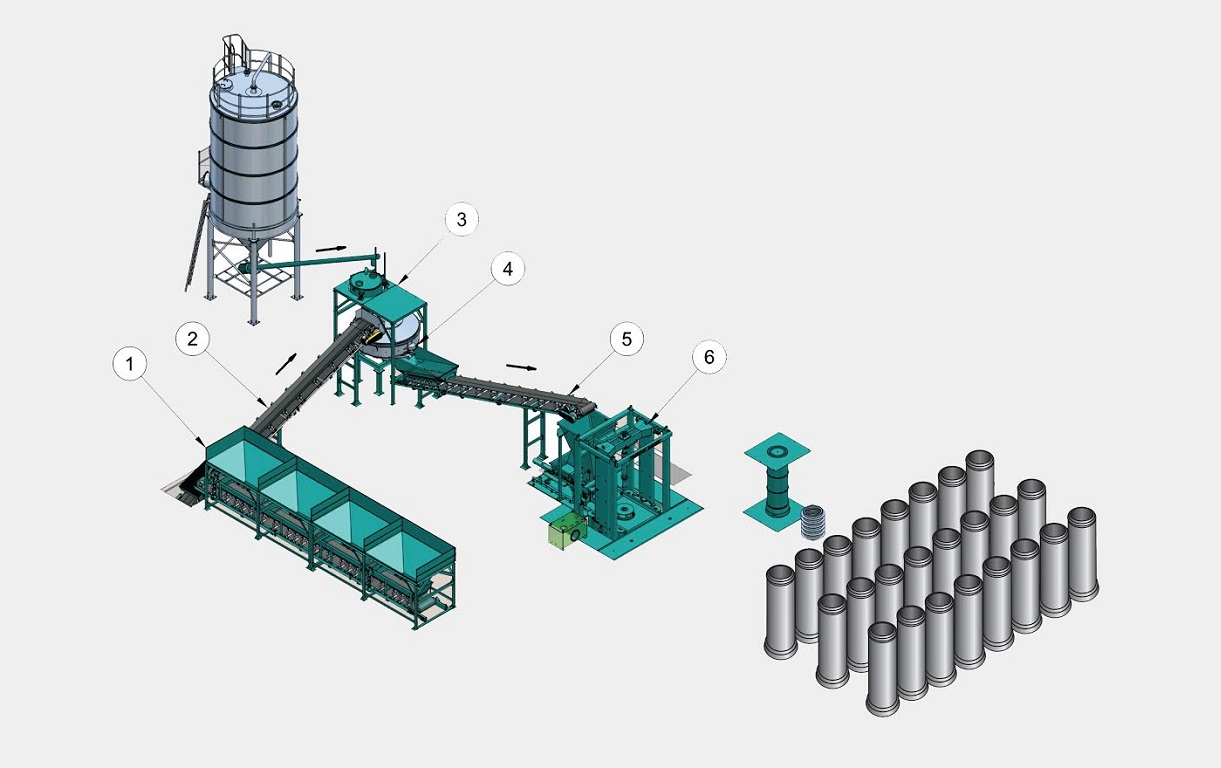

The Complete production line consists of:

4 Bin Aggregate Batching Plant

Power: 7 (H.p.)min

Inclined Aggregate Conveyor 600mm Wide

Power: 5 (H.p.)min

Cement Weight Batcher with Support Structure

Power: 5 (H.p.)min

Planetary Mixer - Model 1125

Power: 40 (H.p.)min

Mud Belt Conveyor 600mm Wide

Power: 5/7.5 (H.p.)min

Pipe Machine - Model # Mach 1200 | 1600 | 1800

PPM Semi Automatic

Specifications of Concrete Pipe Making Machines :-

Concrete Pipes are the most versatile, durable and economical conduit material. They are integral components of our infrastructure being employed in a wide range of applications. Precast Concrete Pipes are widely used for water mains, Sewer, Culverts and in Irrigation. Today, Concrete Pipes are being manufactured commonly on conventional spinning system process and latest Vertical Vibrated Casting Process.

1. Fully Automatic Machine

2. Semi Automatic Machine

3. Manufactured in India with imported Technology

4. Output Upto 100 pipes per shift, varies with the diameter, Upto 2500mm

5. Value Added Products

| MODEL | DIAMETER | OUTPUT/SHIFT |

| MACH 1200 | 300-1200 | 40-60 |

| MACH 1600* | 300-1600 | 30-60 |

| Semi-Automatic | 800-3500 | 20-30 |

*For Two Station Machine the output is 100 pipes per shift

Advantages of Fully Automatic machine MACH 1600 over Semi Automatic machine.

1. Infrastructure: Investment requirement is more in semi automatic machine as a heavy shed with gantry is required. The cost of which is 50 – 60 Lacs as compared to a light shed in Automatic Machine. The cost is 20 – 25 Lacs.

2. Equipment: Cost of EOT crane 25 – 30 Ton is 30 – 40 Lacs also limited access with in shed only. Whereas a Forklift of 8-10 Ton used in the Automatic Machine is around 20 – 25 Lacs. Therefore, the overall cost of equipment and shed is about 50 -60 lacs more in Semi Automatic.

3. Power: Electricity consumption is 20% higher in Semi-Automatic (Because of EOT crane) as compared to Automatic.

4. Man Power: more Man Power 12-15 is required in Semi-Automatic as compared to Automatic.

5. Production: In fully automatic machine moulding & demoulding is auto driven so production is faster and more. Whereas in semi automatic machine moulding and demoulding is manual results lesser production (50%)

PHOTOS AND APPLICATION OF PRODUCT PRODUCED ON MACH 1600 MODEL

MITERS & SIDE OPENING

PRECAST BOX CULVERT :-

In the recent past, the construction of short-span bridges with precast concrete box culverts has revolutionized the industry. Today, we have Pakona pipe machines using which we can make precast concrete box culvert components so much quicker and easier as compared to casting a short-span bridge in the field. Here are key benefits that make precast concrete box culverts the optimal solution for short-span bridges.

| Time :- Precast concrete box culverts exponentially decrease the time that it takes to build a short-span bridge. |

| Money :- When considering lifecycle costs – the total cost of the bridge over its lifespan – precast concrete short-span bridges will almost certainly provide a cost savings. When considering the total cost, including on-site labour and installation time, pricing is comparable or even less when using precast. |

| Quality :- Because all precast concrete box culvert components are constructed in a climate-controlled factory by skilled production team, the quality is unparalleled. When constructing a bridge in the field, there are many factors that can derail quality |